TL;DR Go get a Wing Logic MSHD wing right now. The wing is over 2.5 lbs lighter than the previous version, makes more downforce, and is just $350 for a 65” wing!

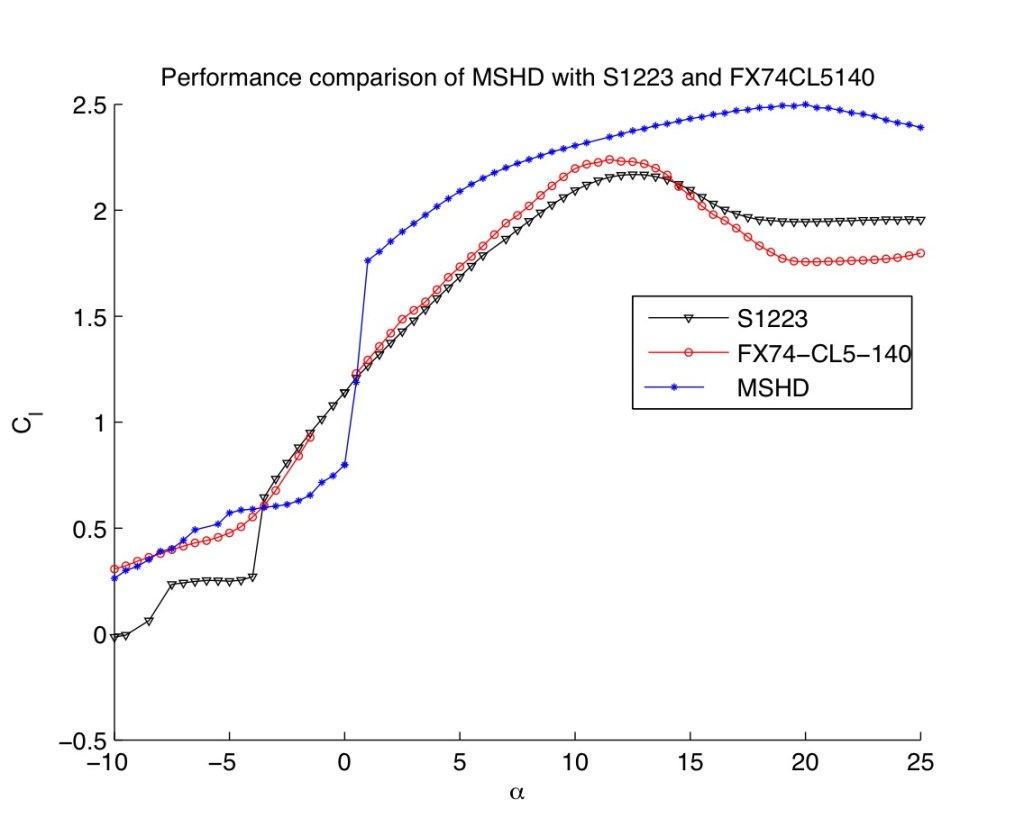

In my article on Car Wing Comparisons, I review many of the airfoils used in motorsports. The wings I researched for that article were mostly from the Airfoil Tools website, and designed as airplane wings. Of those, the best performing wing was the low-Reynolds high-lift Selig S1223.

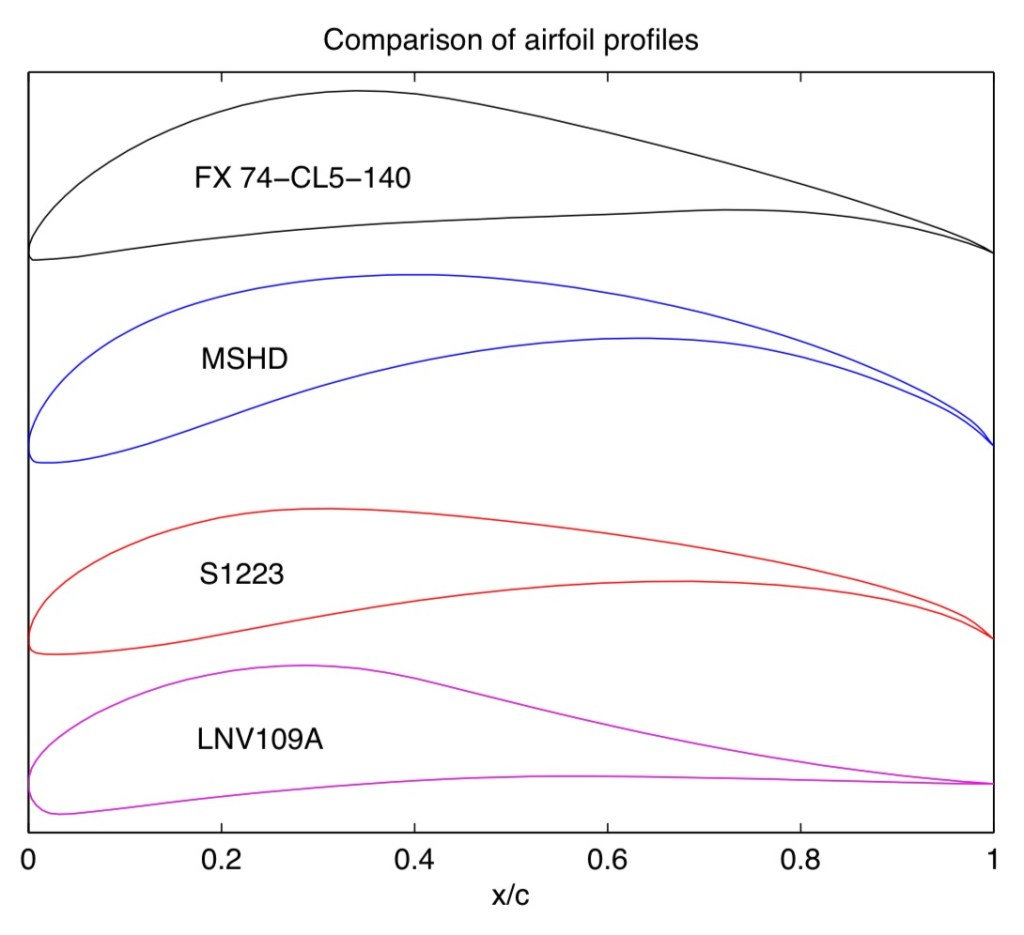

But cars don’t need to get airborne, and so motorsports wings can be designed differently than airplane wings. In Enrico Benzing’s book Wings, he examines the various factors that make car wings different than airplane wings. I’ll do Benzing a great disservice and sum up his entire book in a sentence: car wings can have more camber and thickness, and the location of the maximum thickness is important.

Benzing’s research was groundbreaking 13 years ago when it was published. Since then, car wings have continued to evolve from high-lift airplane wings, to motorsports-specific designs. I built a S1223 wing and tested it in the wind tunnel vs two wings in Benzing’s book, and the S1223 airplane wing did not perform as well as either of the car-specific wings. However, the best performing wing I tested isn’t in Benzing’s book.

The wing that won my wind tunnel comparison test was a new airfoil called the MSHD. The 144-page thesis paper by Sriram Saranathy Pakkam goes into great detail on the airfoil’s design, and how it compares with other popular wings.

It seemed too good to be true, so I had to build one, try it on my car, and test it in the wind tunnel. It outperformed my homemade S1223, a Procar Innovations wing (Benzing 183-185), and a 9 Lives Racing wing (Benzing 123-125). These results are in my first wind tunnel report.

The shape of the MSHD looks a lot like a Selig S1223, but with more camber, and an absolutely wicked trailing edge. The trailing edge was difficult for me to build in foam and fiberglass, as it’s nearly impossible to get the edge thin enough and still retain some strength. So I’m pretty sure the performance of my DIY wing could have been improved if I made it in some other material.

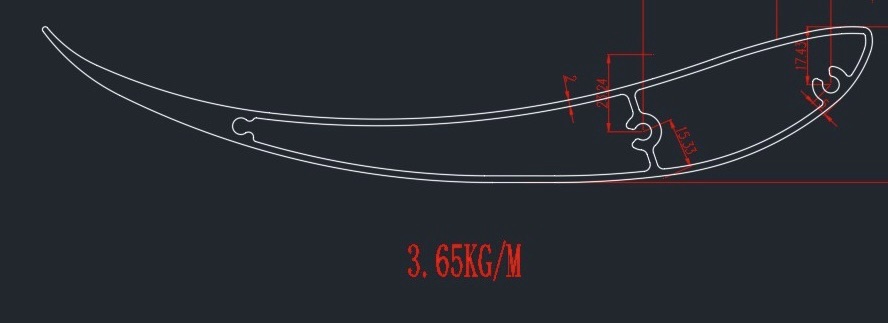

Carbon fiber is the best material, but is banned in series like Champcar, and can be prohibitively expensive. A better way to build this wing for the average club racer would be to extrude it out of aluminum. This would allow a very thin and strong trailing edge that closely follows the ideal geometry. And if mass produced, it could drive the price down to where even cheap bastards like myself would buy one, rather than DIY an inaccurate copy.

Wing Logic

So now that you know the backstory of why the MSHD is the motorsports airfoil of choice, let’s move onto the part of the story of how this wing gets mass produced. It starts with Michael Jui, an entrepreneur who was already doing stuff in motorsports. If you’ve ever shopped for a new helmet and sorted on lowest price, you’ll see Conquer helmets at the top of the list. Conquer is one of Michael’s companies, and embodies his philosophy: high quality at a low price.

Michael contacted me and asked if I could test his extruded aluminum Wing Logic wing in the wind tunnel. That information is here on my site in the article Wing Logic vs 9 Lives Racing, and also more in depth in my second wind tunnel report. In short, the Wing Logic wing did pretty well for being based on an airplane wing. But the 9 Lives Racing wing made the same downforce for less area, meaning it was more efficient and also weighed less. In the end I opined that the 9 Lives was their better choice if price was no object, but that Wing Logic was a fine wing for the budget conscious.

After that test, Michael and I got talking about a new car wing, and I suggested he build one using the MSHD shape. I advised that he should make 10” and 12” chord sizes. Alyssa Merrill, who does all my computer designing and 3D printing, sent Michael the CAD file we used to 3D-print Steve Leo’s foam wing. And with that, Michael’s engineer got started on the two wing designs.

Weighty decisions

Michael sent me the engineer drawings for both the 250mm and 300mm wings. The larger wing was going to be almost 150% heavier, and I’m not sure how many people would want over 20 lbs high up above their car. The end result is that Michael has only the 250mm available at this time, and I think that was a good call.

Weight is an issue for aluminum wings, and so I asked Michael if he could have his engineer lighten it up and make it thinner? Not possible. The wing was already at the minimum thickness for making an aluminum extrusion. So I suggested reducing the number of end-plate bosses from four to three, and moving one of them to the rear of the wing. I also suggested removing one of the spars. This resulted in a minor weight savings of .166 kg per meter, or 1.785 ounces per foot.

On a typical 72” wing this is only a savings of 11 ounces. But as the saying goes, if you concentrate on the ounces, the pounds take care of themselves. Also, the location of that weight is important, as wings are typically the furthest distance from the center of gravity.

I also felt the endplates on his original wing were too heavy. At 10” x 5.5”, there’s very little flex to them, and so there’s no need for such a heavy endplate. Thickness was originally around 9 gauge, and is now about 13 gauge, which is a savings of 7.3 ounces.

The Wing Logic endplates are rather small compared to what you see on most wings, and you might wonder how they perform. In my 2nd wind tunnel report I tested the standard Wing Logic endplate versus larger endplates, and the results were about even. There was slightly more downforce and drag for the larger endplates, and slightly less from the smaller ones. But the overall efficiency of the car remained about the same with both, and so small endplates are just fine.

Another decision not to be taken lightly is whether or not to put a Gurney flap on the wing. 9 Lives Racing has a slot in the trailing edge of the wing for a Gurney flap, and I advised specifically against this. The problem is that this adds weight, but more significantly, it changes the rear geometry of the airfoil. If you compare a Be 123-125 airfoil with a 9 Lives, they are identical… except for the trailing edge, which is far too thick on the 9 Lives.

How much does this change the performance? I don’t know. But if the wing performed better with that thicker rear section, we’d see wings designed like that from the get-go, and we simply don’t.

The other way to do a Gurney flap is to mold it in. This is what Michael did on his original Wing Logic, adding a 1/4” Gurney flap as part of the extrusion. While this is economically efficient for the customer, I advised against doing that on the new wing.

First, because it’s just so easy to tape on a Gurney flap. The flap is on the pressure side of the wing, and so simply using duct tape to fasten it down makes for easy application of any size wicker. Some people may want to use double-sided 3M tape or rivets for peace of mind, and I can’t argue with that. I use 1/2” aluminum angle for a Gurney flap, and don’t mess with different heights. Changing wing angle has about the same effect as changing Gurney flap height, and so nobody really needs multiple sizes; a slot for a custom-sized Gurney flap is just more gimmicky and expensive shit I can do without.

The other reason not to mold in a Gurney flap is it can be trickier to set up it up as a dual element. Gurney flaps can absolutely be used in a multi-wing setup, but the wing overlap and gap distance become crucial and finicky variables. You can read about that elsewhere on this site, but rather than having a customer suffer those headaches, I suggested to leave the trailing edge sharp.

So you might be wondering, how does the MSHD behave as a dual element? The maximum coefficient of lift goes from 2.3-ish as a single element to almost 4 as a dual element. Yowza. Also, there’s a very soft or non-existent stall. So as good as this is as a single wing, it might be even more remarkable as a dual. (I have one set up for a dual element, but more on that in a future article.)

Unboxing

It took a year from concept to reality which is probably a short development time, but it seemed like forever. The wing came really nicely packaged, with protective foam all around. My first thought upon unboxing it was “holy shit that’s a lot of camber.” My next thought was “good lord that’s a wicked trailing edge!” And then I thought, “man, this is pretty light.”

The chord measures 250mm, or about 9-7/8”. Available lengths are 60”, 65”, 71”, 72”, and 74”. Most racing series limit wings to body width, but if you are unbound by rules, wider is better. If you race in a series that has a 701 square-inch limitation, you’ll want the 71” wing.

End plates are included in the box, and as stated earlier, they are the same size and shape as the old endplates, just thinner. They aren’t pre-drilled, but there’s an included template for that. The M6 bolts are stainless button-head, and thread quite deeply into the end of the wings, which I appreciate. (For reference, 9 Lives uses four M5 bolts, PCI uses two M8.)

Bottom mounts are included, but the holes are oddly large. I typically use M6 hardware for wing mounts, but these are much larger. Which is fine I suppose, just different. But since I’m going to do some back-to-back testing, I made up my own mounts using a 9 Lives pattern.

I’m sure someone wants to know what the Wing Logic MSHD looks like next to the industry standard 9 Lives wing. MSHD has more camber, and a much finer trailing edge.

I weighed the 65” Wing Logic MSHD with endplates and wing mounts and it came in at an even 14 lbs. The original 65” Wing Logic was 16.6 lbs, so this is a significant savings over the old wing. Incredibly, the 65” x 9.8” MSHD weighs even less than a 9 Lives Racing 64” x 9.2” wing, which came in at 14.6 lbs with the same mounts and endplates.

Now this is the older 9 Lives wing that I weighed, and what is now sold as the “Express” wing. 9 Lives Racing has a newer wing, which is the same shape but has been lighten somewhat. I don’t have one, and so I can’t compare the weight on that.

I have to say, it’s really satisfying to have the Wing Logic MSHD in my hands. My role in helping bring this to market was very minor, but I’m chuffed to have had any input in this, and to see it IRL

It’s bigger, lighter, and has more downforce than any other aluminum wing on the market. And it’s currently on sale for $350 in a 65” wing!

CFD

A lot of wings get developed, sold and evaluated based on CFD alone, which is a highly suspect practice. CFD is a tool to get you part of the way there, and you to need to follow up with a wind tunnel or track testing. That’s how the F1 teams do it.

Unverified CFD results in ridiculous claims of downforce and efficiency, and optimizations that show up in the computer world, but not in the real world. I’ll give you an example: I tested some CFD-designed endplates that were supposed to increase downforce and reduce drag over a standard rectangular endplate. But in the wind tunnel, the CFD designed ones were actually worse than a plain rectangle I cut out of a street sign. (This data is in my first wind tunnel report.) Moreover, I flipped the CFD endplates backwards to see what would happen; the data showed very small changes to drag and downforce, but the same overall performance. So whenever I see something that is developed and marketed completely from CFD, I distrust it.

However, I do trust the CFD from Kyle Forster, since his CFD models are much more accurate, and he puts the wing on a virtual car, rather than relying only on free stream simulations. I’m not going to delve into the computer stuff here, but if you’re wondering how the old vs new wings compare, Wing Logic published the full CFD comparison of the original Wing Logic versus the new MSHD.

Note that the MSHD CFD data stops at 10 degrees AoA, and as you saw from the original thesis paper, the MSHD can be run at even higher angles. And so while these numbers look great on paper, I believe they can get even better.

Based on the CFD, and more importantly, the testing I’ve done on my own DIY MSHD, I fully expect the new Wing Logic to outperform every other wing I’ve tested, and relocate all my other wings to the recycling bin.

Track testing and wind tunnel

I’ll schedule wind tunnel time later this year, and will test the MSHD as a single and dual element. I have some different endplate ideas, and a few secrets I’m not sharing yet that could be game changers. Subscribe to the blog, you don’t want to miss that.

I’ll also be track testing the wing on a few occasions. I’m racing with Lucky Dog at PittRace and will be able to A/B test the MSHD vs 9 Lives wings on the Miata I took to the wind tunnel. So that will be great to get real world data that I can use to compare with the wind tunnel data. And I have some other track tests scheduled for Watkins Glen and Pineview, before going back to PittRace one more time (the final time, ever).

I’m so excited to do some testing on this wing over the winter! Currently on the 9LR dual element, but hoping I can balance it out with just the single MSHD wing for track. Probably will pair it with either the 9LR flap, or the eBay flap I have (similar to what you did) for Autocross though.

LikeLike

Weather permitting, I’ll be testing the 9LR dual element vs MSHD in a couple weeks. I plan to set up the MSHD as both a dual (eBay flap) and single (with Gurney flap). Looking forward to comparing notes with you.

LikeLike