CJ Oldham began autocrossing in 2012 with a V6 Camaro. Two years later he bought a 1993 Miata, with the intention of running the popular ES class. However, the one-wheel peel was no good for dodging cones, and this lead him to installing a 1.8 BP4W motor (VICS not VVT) and drivetrain.

While the 1.8 was an improvement, CJ wanted more power. He looked at Kmiatas, but had seen some people have issues with that swap, and in the end, taking an inline four out and replacing with another just had no interest for him.

CJ’s dad is also a Miata guy, and had an MSM with typical mods. But as it goes with dads and sons, CJ didn’t go the same route, and he chose a Rotrex supercharger. This would fit with his goal of keeping things simple, by using as many Miata parts as possible.

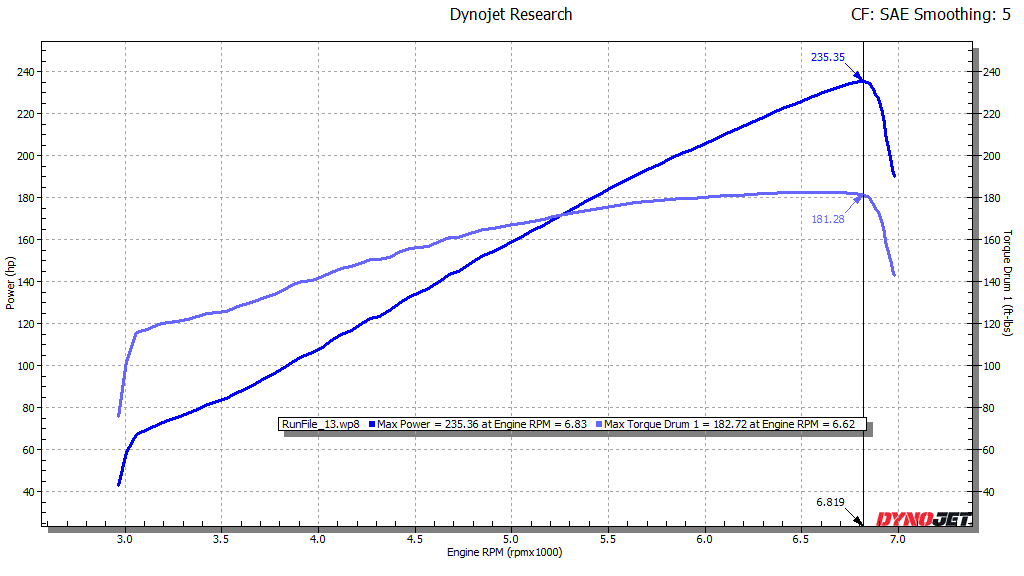

Which is not to say the build was easy. Apparently Trackdog Racing had a new machining vendor at the time, and this caused the engine to have an appetite for belts. But once the belt alignment was sorted out, things have gone swimmingly. Check out the dyno graph, with 235 hp and 180 torque at the wheels.

You can see from the dyno chart that the Rotrex supercharger builds power linearly from down low. Looking at that torque curve, which peaks at redline, I have to wonder how a BP05 (1994-97) would do in comparison, possibly not much different.

The gradual buildup of power is kinder to the driveline, and as the revs rise, the boost builds, and you have turbo power at the top end. As good as modern turbos are, they still rely on exhaust gasses to spool up, whereas a supercharger gets going immediately. Theoretically, the SC should have better throttle response and modulation low in the rev range.

How important is that? Speaking from personal experience, there was that one time at band camp (Pineview Run) when my normally aspirated 1.6 Miata beat a K24 Miata and took its lunch money. Stefan, the owner of the K24 (of Napp Motorsports) turned faster lap times in my normally aspirated 1.6 BP than he did in his 2.4 liter K. Hell, we both did. If you don’t believe me, I do a deep dive on the data in that article, and what it comes down to is we were both sooner to full throttle, and that was more important than top end power later on. Less is sometimes more.

But even if gradual power is easier to drive, and easier on the clutch, transmission, and ring gear, there’s no way you’re going to get a NA6 driveline to survive a Rotrex. Like any sensible person, CJ had already replaced the 6″ ring gear with a later 7″ ring and pinion. He also added a Torsen, which was really the prime motivator for the whole project. To this he added a Supermiata organic clutch and lightweight flywheel.

The final drive has a 3.9:1 ratio, which gives a theoretical top speed of 150 mph at 7000 rpm. Personally, I might opt for the 4.1 because that’s still good for 143 mph, and since nobody wants a 4.1, they are a lot easier to find and replace. The 3.9 is going to buzz less on the highway, though.

CJ is not one to scrimp on anything, and so he has Xidas in 800/500 spring rates. Some people might say those springs are on the lighter side for a car with aero, but I heartily approve of a softer car.

Front brakes were upgraded to Wilwood BX11, but since modifying the car for NASA TT4, he’s supersized to the BroFab Bigger Brake Kit with 1.25” AFCO rotors. The rear brakes are NB Sport rotors with NA6 calipers. Wheels have been similarly upsized from 15×9 FM Kogekis shod with 225/45 R15 V730s to big boy 15×10 Dekagrams with 245 Toyo RR’s. This is a proper Miata.

CJ hasn’t gone off the deep end adding lightness, and in fact has all of the sound deadening and carpet still in the car. As such, the supercharger whine is quite subdued and sounds more like a soft jet engine than the whirling and whining of gears. The car weighs in at 2500 lbs with driver, and that calculates to around 10.6 lbs/hp. At the speeds this car is capable of, you’d better have some aero, so of course it does.

Aero

CJ Oldham designs and manufactures most of his parts. He went to school for nuclear engineering, but has always had an interest in the mechanical/aerospace side. And it shows. He starts by scanning the car with Revopoint products, and then designs most of the parts in Fusion 360. This allows him to rapidly produce 3D printed parts with great accuracy.

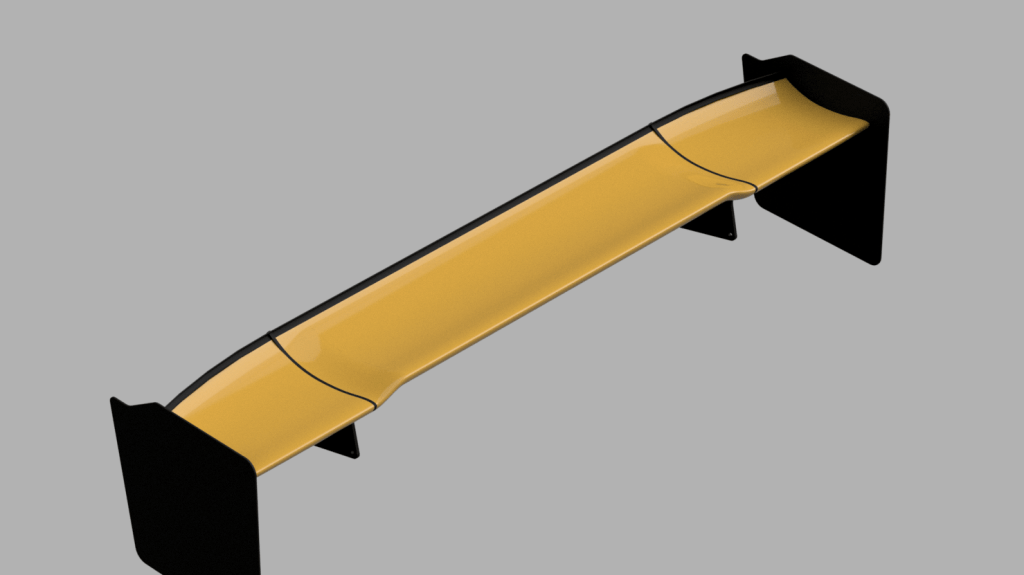

For example, there’s his wing. After hearing about about the MSHD airfoil, I added it to my article on Car Wing Comparisons and planned to make my own shortly after. Damnit if CJ didn’t beat me to it! My construction methods take slightly longer, while he was able to quickly print a wing in ASA. He chose a 64×11 size, and when you factor in the slight taper at the ends, you’d bet it fits exactly within the GLTC maximum size. That level of detail makes that you question how many rulebooks he’s reading.

Indeed, he also has 12″ side skirts, which are the maximum size allowed in the Max category for SCCA Time Trials racing. This is a person who’s level of detail extends in all directions, including a very lawyer-like reading of many rulebooks!

Of all the masterstrokes on this perfect Miata, the NB-esque nose on his NA Miata is what does it for me. Big plastic airdams are the lazy man’s way to improved front end performance, and to most people, they look like Tupperware. But CJ shows not only his ability to design function, but a pleasing form. Take a look.

In the image above, I especially like the pic that shows the red NA nose underneath the new one. You can see how much more coverage CJ’s nose has by comparison. In the pics below, you can see that the Racebred splitter, front tire spats, and brake duct holes were clearly not afterthoughts, and integrated nicely.

After mocking everything up, CJ did a great job finishing the work, which results in a near OE finish. Bravo my man, brav-fucking-o. It’s not just the nose that is 3D printed, but the hood and fender vents, as well.

CJ and his dad have done all the work themselves. Other than going to a shop for dyno tuning and alignments, it’s all DIY. I just love that spirit, and the execution is near flawless. Damn dude, you just totally raised the bar.

So.. Where do we buy one of these bumpers? Or the print files?

LikeLike