If you haven’t read my previous post on Low Speed Wings, I came up with the following design parameters for low-speed:

- Massive chord – Wings don’t perform well at low Reynolds numbers. At the speeds cars travel, the larger the chord, the more efficient a wing is.

- High lift at low Re – I’ve chosen the Selig 1223 RTL airfoil because it has the highest lift. Drag is of no consequence at low speed, and so I can set the wing to maximum angle of 15 degrees.

- Mass centralization – I’m designing this wing for low speed race tracks which are all about quick changes of direction. If you think about it, wings are located in the worst possible position for this; high, wide, and at the polar end of the car. Increasing the chord and making the wing narrower goes hand in hand toward mass centralization.

- Size — I’ll mount the wing by screwing into the ends, and with wing stands in the trunk gutter, that’s a wing that measures 41″ long. I’d like to keep the size under 700 square inches, so that’s a maximum of 16.5″ chord.

Getting the wing profile

- Start on the Selig 1223 RTL page and click Send to Plotter.

- Change the Chord to 406mm; this is 16″.

- Set the pitch to -10 degrees. This is optional, but I like to see a wing with some realistic rake to it.

- Select the checkbox for Reverse so you can see the wing right side up. Optionally select Camber line.

- Click Plot.

- Click Download PDF file.

- Print it out.

Making the wing

I put the airfoil printout on a piece of plywood and cut it out on a band saw, then replicated that a few more times. If I end up building more, I’d do them all on a router and save myself a bunch of time, but the bandsaw is ok for jobs like this.

I assembled the forms, which are called ribs in airplane construction, and made a couple cross pieces, which are called spars or stringers. The front is a wood dowel screwed into the end ribs. I epoxied all of this together.

I then covered the frame with a thin layer of plywood. I used a single laminate of maple, but any veneer would do. Heck, cardboard might work, this is just to give it shape and hold the glass.

Then I glassed the whole thing with 6oz fabric. I made some mistakes. One is I thought it would be clever to fill the void inside with expanding foam. Well, that really swelled up inside and broke through the plywood, which I had to patch with fiberglass. I made some other small detail mistakes, and if make another, it will be easier and lighter.

Even with some silly mistakes the wing is light. I weighed the wing before fiberglassing and it was exactly 5 lbs. After glassing, filling, and fixing mistakes it weighed a little over 6 lbs. Thats 40% of the weight of an aluminum wing with the same plan area.

End plates

A wing this big should ideally have enormous end plates, but I wanted to keep them under 144 square inches, because some racing rules regulate to that size. I had some scrap street signs 18” wide, so to simplify things, I used that as the main dimension. I set the top of the end plate level with the camber of the wing, to make setting wing angle easier.

For the bottom shape, if I’d made the end plates rectangular, they’d be 8” deep. Instead I put a slight angle on the bottom edge to put more area at the front of the wing, where there’s more negative pressure, and so they are 9.5” at the forward edge and 6.5” at the rear. I rounded the corners to avoid cuts, and they measure somewhere under 144 square inches now.

My local scrap yard sells aluminum street signs for $1 per pound. Most street signs are made out of .064” aluminum, which weighs .9 lbs per square foot. And so the end plates, which are also the wing mounts, add 1.8 lbs to the wing and represent $2 worth of material.

The wing is held up by the end plates, so these need to be super strong. So I screwed them into the sides of the wing with five screws on each side and epoxied them on for good measure.

Gurney flap

All wings should have Gurney flaps, especially low-speed wings. On airplanes the guideline for height is is 1-3% of the chord, with low heights offering better efficiency and taller heights making more lift. On cars you often see larger wickers, and 5-10% is not uncommon.

I bought a piece of angle aluminum which is 3/4″ on one side and 1/2″ on the other. This means I can reverse the wicker, to use either height (which corresponds to roughly 5% and 3% chord). I installed it with screws through the top, since the pressure side of the wing doesn’t matter much.

I found some data on Gurney flaps on the Selig S1223 wing, and you can see they are quite effective.

| Flap height | Cl |

| None | 2.25 |

| 1.04% | 2.36 |

| 1.56% | 2.34 |

| 2.08% | 2.43 |

| 3.12% | 2.46 |

| 4.17% | 2.52 |

Finishing details

The total dimensions are 41″ x 16″, or 656 square inches. It weighs 9.2 lbs with end plates and Gurney flap, ready to bolt up. It cost me all of $40 in materials, and probably 8 hours building it, but some of that time was fixing mistakes. I decided to leave it unfinished rather than paint it. I can see all the mistakes I made, and this will serve as a reminder of how not to do it next time.

The end result is a very narrow wing, with an absurdly large chord. It’s definitely unusual looking! So how does it work?

Testing

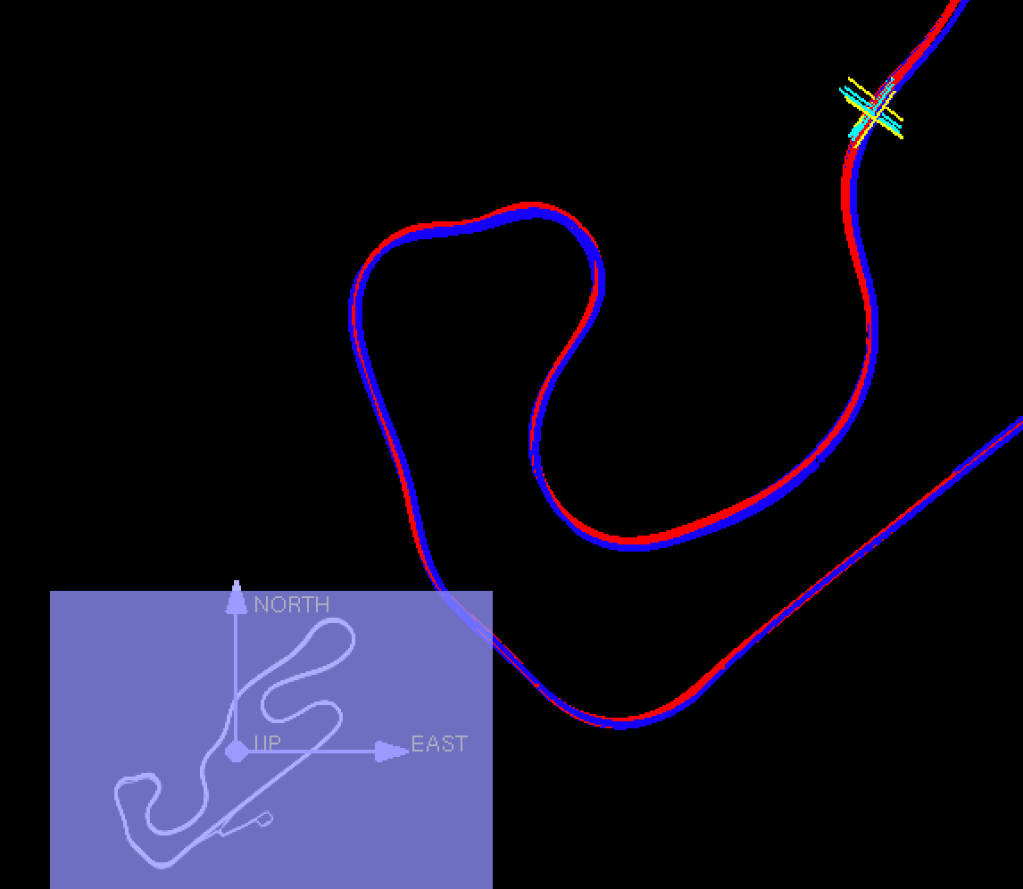

To test the wing I had my teammate Alyssa Merril A/B test this versus a 64″ 9 Lives Racing wing at New York Safety Track. This was the same day she, Mike, and Chris set Miata track records. Alyssa went .3 seconds faster on the 9 Lives Racing wing, noting that the high speed sections gave more confidence. After digging into the data, the wings were actually very evenly matched except for the fast esses here:

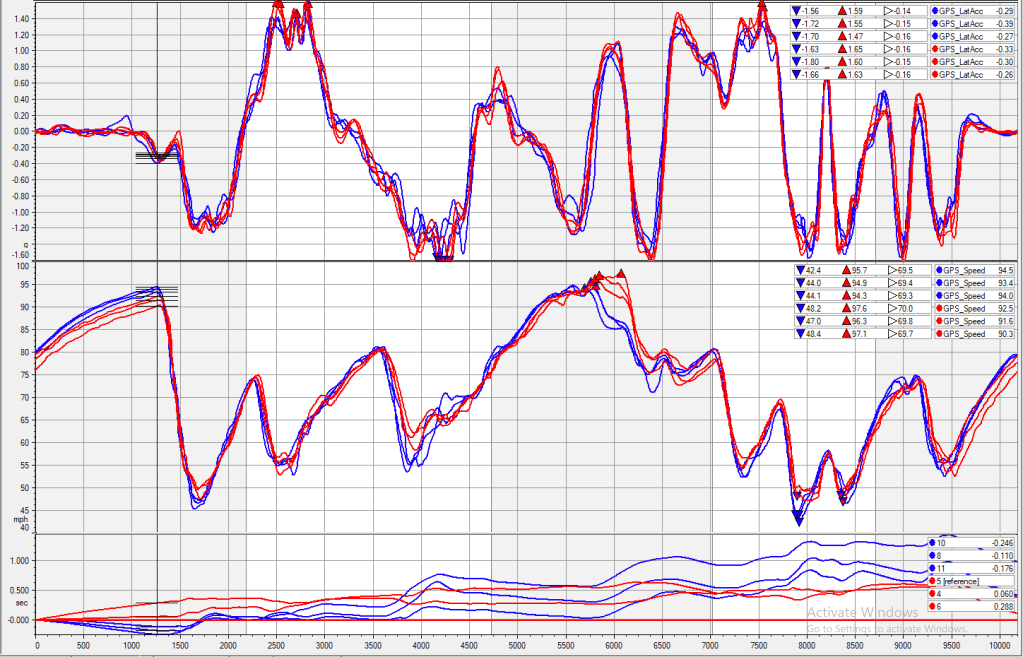

Here’s data from sessions 30 minutes apart, and so fairly similar track conditions. I chose the three fastest laps for each wing, since there was some traffic and other noise in the data. Lateral Gs on top, and the typical speed trace and time graphs on the bottom.

- The Selig wing had less drag and consistently went to a higher top speed than the 9 Lives wing. Not expected.

- The low speed corners, where the Selig was supposed to work better, actually show slower min speeds. Not expected.

So the low-speed wing is actually a low-drag wing? That’s what it looks like. Aero often throws you curve balls, this one is going to take some more investigation. From the wing visualizer tests I did, I know that the Selig wing isn’t benefiting from the undisturbed air at the ends of the wings, and so basically all the air hitting the S1223 is turbulent, and with a standard Miata hardtop roof shape, a wider wing works better. I have a new hardtop that’s designed to reduce turbulence and feed the middle of the wing, but more on that some other time.

So cool to see this and your results. Did you do any tufting, etc? It would seem to be a good race wing, protecting you down the straights and holding up everyone in the slow bits 🙂

LikeLike

I didn’t do any tuft tests, I’m not sure what that would have told me. I have a different roof that might make this wing perform a lot better.

LikeLike

I don’t know what your rules are but trying a higher gurney might be helpful for speed, and don’t forget all the drag you lost by narrowing the wing. Maybe more angle too. This profile has it’s best L/D at about 6 degrees and I would think you could go higher than 1o degrees. Really cool, what you’ve done!

LikeLike

I’m looking into doing a 3D wing sections for my miata. Would be interested to see the effects of vortex generators at the rear of the Miata hardtop to delay separation at the top of the rear glass, which I hope would put more air underneath the wing, especially in the middle where you reference it is having a tough time. What are your thoughts? I’m planning to run some preliminary CFD tests, but I’ve long wondered if miata hard top + wing combinations would benefit from VG’s.

LikeLike

I tested this already, search the site for vortex generators. I didn’t experiment too much with location, but they made things worse. You might also look at AJ Hartman’s wind tunnel tests where he put VGs on a Mustang and similarly lost downforce. If the rules allow it, get the wing higher or use a fastback.

LikeLike

Glad to see you back at it!

LikeLiked by 1 person